Suspended Solids Density Meter

Get in touch! How can we help you with your water and wastewater sampling needs?

Suspended Solids Density Meters are ultrasonic sludge & slurry density meters. Inline TSS analyzer or throw-in TSS probe sensors monitor total suspended solids and provide continuous readings. They excel in challenging applications such as thick concentrations and small pipes. Ultrasonic sensors are inherently safe – no permits, no approvals needed. Readings are not affected by the color of fluid or particulates. Installations include pipes, open-top tanks and clarifiers, with the added capability of automating pumps, helping to optimize dosing, underflow density and feed density. Whether monitoring in water, wastewater or process industry applications, Markland Suspended Solids Density Meters will help you maintain your concentration.

Suspended Solids Density Meter — Get the Markland Advantage

Let Markland’s total suspended solids monitor help you stay in control.

- Know real-time TSS readings of silt, sludge (including RAS and backwash sludge) and process slurries, in clarifiers, open-top tanks, pipes and recirculation loops.

Markland sludge density meters & slurry density meters use ultrasonic TSS sensors.

- Non-nuclear sensors are inherently safe, and excel at providing percentage suspended solids readings (%SS) in thick concentrations and small pipes.

- Concentration readings are unaffected by color of fluid or particulates.

Choose from the non-intrusive inline TSS meter or throw-in TSS probe.

- Both styles of total suspended solids meters are simple to install, calibrate and clean.

Reduce material, energy and maintenance costs by automating pumps.

- Help fine-tune polymer dosing and reduce wear-and-tear on pumps.

A total suspended solids meter helps maintain preferred underflow sludge density.

- Benefits include improved outflow available for re-use, and data to aid in fine-tuning variables on thickening equipment.

- Avoid pumping thin sludge.

A suspended solids slurry density meter helps maintain your desired feed density.

- Continuous readings of %SS enable calculation of real-time solids mass flow, promoting efficiency and effectiveness in the manufacturing process.

Determine the total suspended solids analyzer that works best for your unique application.

- Samples tested free of charge.

Technical assistance is direct from the designers and manufacturers of this process control equipment.

- Get expert answers to your questions.

Suspended Solids Density Meter — Get The Markland Advantage

Monitor total suspended solids – TSS – of slurry and sludge at water, wastewater & processing plants.

- Stay informed with real-time percentage suspended solids readings of silt, sludge, RAS, backwash sludge, and process slurries.

Use inherently safe ultrasonic TSS sensors to measure sludge and slurry density.

- These non-nuclear sensors are safe, even those used in sludge too thick for optical measurement. Concentration readings are unaffected by color of fluid or particulates.

Choose a throw-in probe or non-intrusive inline spool piece sensor to measure total suspended solids.

- Both styles of TSS density transmitters are simple to install, calibrate and clean.

Measure percent suspended solids – %SS – in clarifiers, tanks, pipes & recirculation loops.

- Have the data at your fingertips for calculating solids mass flow.

Help reduce material and energy costs, and support enhanced dewatering.

- Help fine-tune polymer/chemical dosing and variables on thickening equipment.

Help maintain underflow sludge density by automating pumps.

- Help optimize biosolids or feed density; reduce wear-and-tear on pumps; improve outflow available for re-use.

Choose the TSS density analyzer that works best for your unique application.

- Samples tested free of charge.

Technical assistance is direct from the designers and manufacturers of this process control equipment.

- Get expert answers to your questions.

Markland’s Suspended Solids Density Meter is useful wherever you can benefit from continuous measurement, monitoring and control of total suspended solids (TSS):

- primary, secondary and return-activated sludge (RAS) at Municipal wastewater treatment plants

- backwash sludge from sand or membrane filters at Municipal drinking water treatment plants

- influent and effluent at Industrial water and wastewater treatment plants

- process slurries at Industrial refining and manufacturing plants.

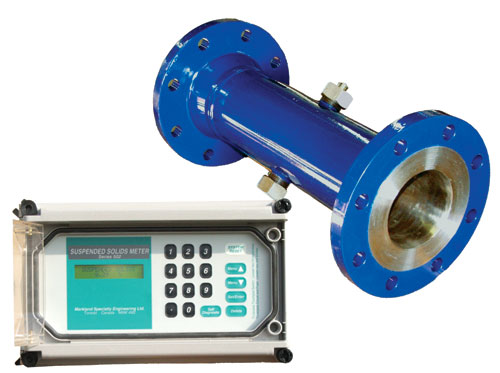

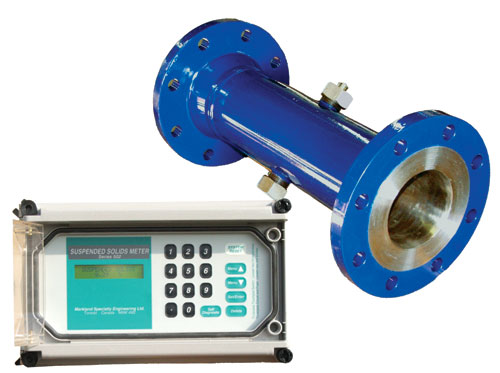

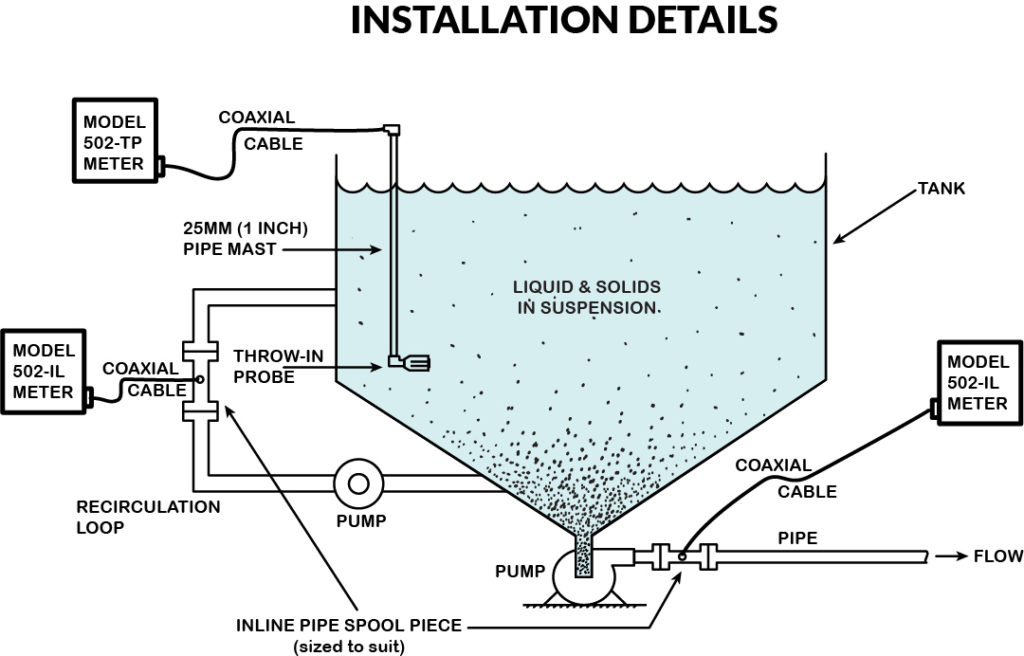

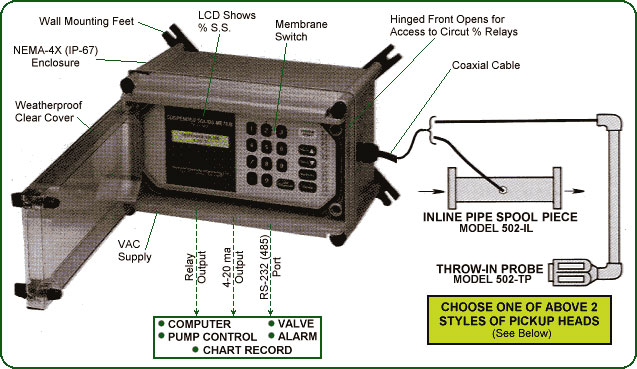

This total suspended solids meter is available as an inline spool piece with a non-intrusive TSS sensor (Model 502-IL), for applications in pipes and recirculation loops, and as a throw-in style TSS probe (Model 502-TP), ideal for clarifiers and open-top tanks. Both models are simple to install, calibrate and clean.

Model 502-IL automates de-sludge pumps to maintain preferred sludge density or feed density.

Model 502-TP measures concentrations at various depths, automatically adjusting underflow pumps when the rising sludge blanket contacts the probe.

Turbidimeter applications, where the suspended solids concentration is less than 0.1% %SS (1000 PPM), are not recommended since there are not enough particles present in the sound path to give sufficient sonic attenuation. Markland suspended solids density meters cannot be used in aerated or heavily-gassing slurries.

It should be noted that Markland’s Suspended Solids Density Meters excel at reading total suspended solids in pipes of 200 mm diameter or smaller, and in thick concentrations.

Markland Suspended Solids Density Meters measure TSS in material as diverse as:

- Primary, secondary and return activated sludge (RAS)

- Drinking water plant sludge

- Hydroxide sludges

- Metal finishing sludge

- Manure for methane gas generation of electricity

- Clay and silica slurries

- Lime slurries for softening water in drinking water plants

- Resins

- Backwash sludge from sand or membrane filters

- Nano and micro particles

- Kaolin clay slurries

- Sugar cane slurries

- Iron ore slime

- Paint slurries

- Aluminum oxide slurries

- Power plant sludge

- Silicone slurries for the coating of plastics so they don’t stick on molds

- Oxide slurries

- Fly ash concentration at powerplants

- Talc

- Porcelain slurry for the manufacture of plates and cups

- Teflon slurry for coating medical equipment

- Garnet powder concentration for a grinding operation

- Fiberglass particle concentration

Markland Suspended Solids Density Meters offer the following features:

- These TSS meters are not affected by the color of fluid or particulates.

- They measure and monitor slurry concentrations too thick for optical methods.

- Set-up is easy, and uses simple push-button calibration.

- The use of safe ultrasonic TSS sensors means the analyzers are non-radioactive, so no approvals and no permits are needed.

- Markland TSS meters can be supplied as an inline spool piece or throw-in style probe.

- The inline spool piece suspended solids density monitor is non-clogging and smooth-bore; its non-intrusive TSS sensor is low maintenance (no protruding parts that could entangle material in the flow, so requires little cleaning).

- These sludge density and slurry density meters are equipped with automatic dynamic damping, to prevent widely fluctuating readings, and advanced self-diagnostics.

NOTE: Markland Suspended Solids Density Meters cannot be used in aerated or heavily-gassing slurries.

Markland’s Suspended Solids Density Meter uses the attenuation of ultrasound to measure silt, sludge and slurry concentrations, and operates in the region between turbidity meters and nuclear gauges.

![]()

CONTROLLER

The Suspended Solids Density Meter continuously fires a transducer, sending an ultrasonic pulse across a gap in the TSS probe to a reflector located directly opposite. The reflector sends an echo back to the transducer. When only clear liquid is in the gap, a strong echo is received, and the meter reads zero. As solids enter the gap, the particles create an attenuated signal as they deflect the sound beam plus absorb energy in the form of particle vibration. The TSS analyzer interprets the received echo based upon calibration parameters to calculate the percent suspended solids. These continuous real-time measurements are displayed on the LCD.

On the throw-in style TSS probe, the reflector is located across the gap in the probe, opposite the transducer. On the inline meter, the reflector is located across the pipe’s diameter.

For large pipe diameters and thicker slurries and sludges where the sonic attenuation is sufficiently high to absorb most of the signal in a single pass, a dual transducer design is used. The reflector is replaced by a second transducer. One transducer transmits and the other receives the signal. The ultrasonic pulse passes only once across the gap instead of twice.

Push-button Calibration

Calibration is a simple push-button procedure, accomplished by filling the pickup head with water and pushing a button on the membrane to automatically calibrate zero. Then the pickup head is filled with a known concentration and that %SS value is entered as well.

If a sample has been withdrawn for analysis, and the actual concentration is not known until a lab test result is received, the meter holds a partial calibration and waits for the actual concentration to be entered later.

Calibration parameters are locked into memory, and are permanently retained, even during extended power failures.

Automatic Dynamic Damping

Non-homogeneous materials, such as sewage sludge, require output damping to prevent widely fluctuating readings, which would not be useable for process control. However, homogeneous slurries, such as Kaolin clay, require very little damping. This suspended solids density monitor uses a running average of many readings to smooth the output. As the difference between instantaneous readings increases (indicating a widely fluctuating signal from a non-homogeneous material), the number of readings used in the running average is increased to damp out the fluctuations. Loss of response time is minimal since the meter takes over a thousand readings every second. When used in slurries that can vary from lumpy to smooth, automatic dynamic damping is useful to prevent unwanted wide swings in the meter output.

Intelligent Microcontroller

Markland’s Suspended Solids Density Meter continuously fires the ultrasonic transducer and interprets the received echo. Based upon its calibration parameters, the TSS meter calculates the percentage suspended solids (%SS) and displays it on the LCD. Sufficient damping is automatically included to create a smoothed output for process control (see “Automatic Dynamic Damping”). The meter’s algorithm includes error traps to prevent improper calibration and Relay settings, and these errors are displayed on the LCD for the Operator to take corrective action. Markland’s advanced self-diagnostic program continuously monitors the meter’s operation, looking for malfunctions, such as broken wires, improper voltage, etc. If a major malfunction is detected, the meter shuts itself down, de-energizes the Relays, and indicates the fault condition on the LCD. The 4-20 ma output can be set to default to zero ma when a major error is encountered, thus signaling to a central computer that something is wrong. Normal operation automatically resumes when a fault condition is corrected.

Set-point Relays

Two independently adjustable set-point relays (high and low) are standard on the Markland Suspended Solids Meter. In order to ignore short-term transients, the %SS must exceed the set-point for 30 seconds continuously, before the relay energizes. Similarly, there is a 10-second delay, which also must be continuous, before the Relay will de-energize. Set-points are entered through the front panel membrane switch and are locked into memory, which indefinitely retains the set-point, even during extended power failure, without requiring backup batteries. The LCD displays the current set-points, which are easily changed using the membrane switch.

This animation demonstrates how the Markland Suspended Solids Density Meter works. The sonic pulse passing through clear water returns a strong echo and the meter reads zero.  Suspended solids absorb some of the sonic energy, making the echo weaker and the meter reads the percentage suspended solids of the slurry.

Suspended solids absorb some of the sonic energy, making the echo weaker and the meter reads the percentage suspended solids of the slurry.

Technical Specifications

| Range | 0.1% (1000 mg/L) to 15% (150,000 mg/L) solids by weight, approximate. Exact range depends upon the sonic attenuation of the particular sludge and the length of the sound path. Contact factory for technical support or No Charge testing of your particular material. | ||||

| Accuracy | ±1000 mg/L to 5% of full scale (depends on sonic attenuation of particular slurry) | ||||

| Linearity | Varies in different materials. Maximum non-linearity at mid-range is usually within 5% of full-scale reading | ||||

| Power | 110/120 VAC, 220/240 VAC, 50/60 Hz, 24 VDC (advise with order). 15 watts | ||||

| Temperature | Liquid: 1°C to 50°C Controller: -20°C to 50°C | ||||

| Pressure | 60 p.s.i.g. (4bar) 400 kpa | ||||

| Outputs |

|

||||

| Calibration | Push-button, Automatic in water (zero) and in known %SS concentration | ||||

| Damping | Automatic Variable Dynamic Damping | ||||

| Response Time | 1 to 30 sec. depending on damping | ||||

| Cable(s) | 15 metres (50 feet) coaxial cable pigtail(s) | ||||

| Enclosure | NEMA-4X (IP-67) Width 343mm (13 1/2″) · Height 229mm (9″) · Depth 200 mm (7 7/8″) | ||||

| Dimensions & Materials |

|

||||

| Approvals |

To receive a quote for a Markland Suspended Solids Density Meter, please complete the form found below.