Sludge Sleuth™ Single Point Sludge Blanket Level Detector

Get in touch! How can we help you with your water and wastewater sampling needs?

Markland’s simple and effective single point monitoring and automatic control to maintain your preferred sludge blanket and supernatant interface level.

The Sludge Sleuth™ Single Point Sludge Blanket Level Detector — Get the Markland Advantage

Single point monitoring and automatic control of the depth of settled beds

Single point monitoring and automatic control of the depth of settled beds

- Beneficial wherever solids are separated from liquids

- Well-suited for municipal and industrial applications.

Optical sensor is ideal for diverse clarification equipment

- LED beam provides accurate readings, even in obstructed/constricted areas such as the inclined plates of lamella separators.

Maintain your preferred sludge blanket and supernatant interface level

- Adjustable solids concentration set-point helps maintain optimum equipment performance

- Help avoid process upsets such as septic sludge conditions, carryover from clarifiers, solids wash-out through DAF unit baffles.

Optimize silt or sludge feed density for enhanced dewatering

- Maximize water removal and avoid pumping large volumes of thin sludge.

- Help reduce energy and haulage costs, and improve outflow for reuse.

Simple installation

- Compact probe design; muffler-style mounting clamps; NEMA 4X enclosure.

Adjustable damping control enables operators to modify the response-time setting

- Staff are alerted when the true settled bed is detected and pumps/valves activated.

Accommodate changes in sludge density

- Easily adjust for thin or thick sludge, slurries, or light flocs, using the concentration control.

Optional delay-off timer is available to help you fine-tune your control

- Access the added advantage that helps reduce wear-and-tear on pumps.

Get answers when you have questions

- Technical assistance is factory-direct from the designers and manufacturers of this sludge blanket level control equipment.

Applications

Single point detection of settled bed levels in:

- gravity settlers, including circular and rectangular clarifiers

- sedimentation basins

- inclined plate separators

- decanting tanks

- DAF units (dissolved air flotation tanks)

- SBRs (sequential batch reactors)

- batch processes

- sumps and pits.

This list provides a few examples of the material able to be detected by this Markland product:

- silt, sludge, and biosolids in primary and secondary clarifiers

- backwash sludge from sand or membrane filters

- resin in water softener intake tanks

- settled mud in tanks

- fly-ash from scrubbers

- grit in sumps and pits.

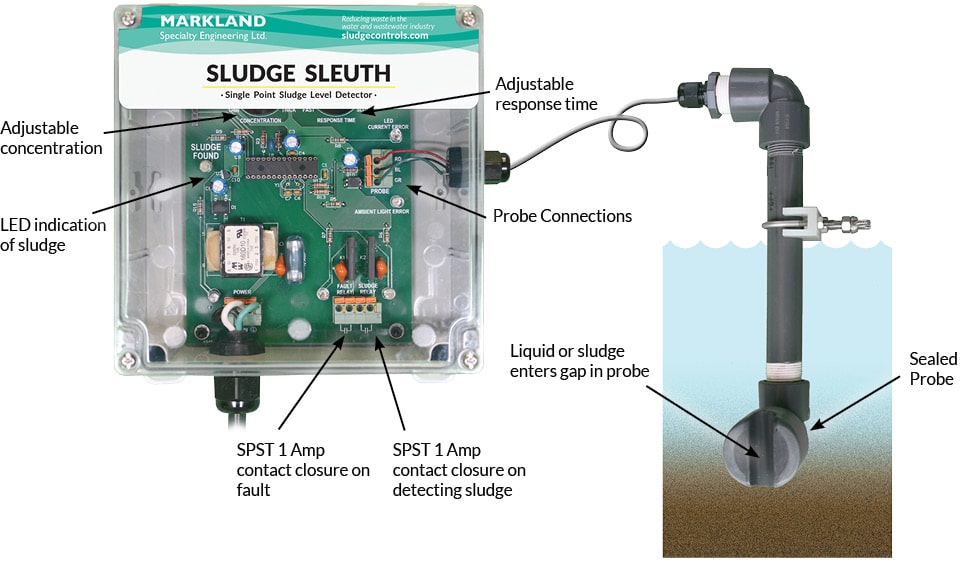

Features

- Simple installation

- No moving parts

- Compact design makes it ideal for obstructed/constricted applications, such as lamella clarifiers

- Adjustable sludge concentration set-point control enables LED beam intensity to be modified to detect liquid-solids interface levels in thick or thin sludges, or in light flocs

- Adjustable response time or damping

- Sludge relay indicates that sludge has been detected by the probe

- Advanced self-diagnostics

- Optional delay-off timer

- Available with the sensor on a rigid pipe mount or hanging from a cable

How it Works

The optical probe of the Sludge Sleuth™ is located at the preferred sludge interface high-level point.

Every second, a LED transmits a pulse of infrared light across a gap in the probe. A phototransistor sensor on the other side of the gap receives the beam of light. If the gap contains air or clear liquid, the detector reads the suspended solids concentration as zero. When suspended solids are encountered in the gap, some beam energy is absorbed. The Sludge Sleuth™ monitors these changes in beam intensity. When it detects that suspended solids have reached a predetermined concentration, it illuminates a LED on its controller and activates a relay that can be used to send an alert to the operator and/or turn on the desludge pumps or valves.

A concentration control allows operators to make adjustments for thick or thin silt, sludge and slurries or light flocs.

An adjustable damping control enables operators to modify the response time setting, customizing the period in which the predetermined solids concentration set-point must be continuously present before the meter takes action.

The Sludge Sleuth™ probe is monitored by self- diagnostics, which turn on local and remote alarms in the unlikely event of a problem with its operation.

A NEMA 4X enclosure allows the detector to be installed anywhere except hazardous locations.

Markland also offers Automatic Sludge Blanket Level Detectors that track the liquid-solids interface level as it rises and falls.

Technical Specifications

| Materials | Probe: PVC Mast: 1″ PVC pipe Clamps: Stainless steel and polypropyline Cable: PVC jacketed Enclosure: Polycarbonate NEMA 4X (IP68) |

| Dimensions | Width: 6.3″ (16 cm) Height: 6.3″ (16 cm) Depth: 3″ (7.6 cm) |

| Cable Length |

10 Meters (33 Feet) – Different cable lengths available |

| Power | 110/220 VAC, 50/60 Hz, 5 watts |

| Output | LED indication SPST 1 Amp solid state relay for sludge indication SPST 1 Amp solid state relay for fault indication |

This animation shows the Sludge Sleuth™ — Markland’s single point sludge blanket level detector — at work. The rising sludge bed approaches the detector’s probe. As the sludge bed, which flows into the probe gap, reaches the predetermined concentration set-point:

- the green LED on the controller lights up

- the SPST 1 Amp relay closes, turning on the desludge pump or valve and/or sending a notification to the operator.

To receive a quote for a Markland Sludge Sleuth™ Single Point Sludge Blanket Level Detector, please complete the questionnaire found below.