Duckbill® Automatic Composite Sampling System

The Duckbill® Automatic Composite Wastewater Sampler for influent, effluent & sewage is the explosion-proof & self-cleaning wastewater sampling equipment that uses compressed air to move samples (no pump, no vacuum system), even up high lifts & over long runs. It can sample multiple sites simultaneously, even in remote locations and cold climates. A stand-out in municipal & industrial wastewater applications, installations for this Simpler Sampler™ include tanks, non-pressurized pipes, sewers, lift stations, sumps, pits and more.

THE DUCKBILL® COMPOSITE WASTEWATER AUTOSAMPLER — GET THE MARKLAND ADVANTAGE

Choose an influent sampler, effluent sampler or sewage sampler that can meet the needs of your challenging applications.

- Move samples up high lifts (80-plus feet / 24-plus meters) and over long runs (90-plus feet / 27-plus meters).

- Sample multiple sites simultaneously, even in remote locations / cold climates.

Markland’s Duckbill® wastewater sampling equipment is inherently explosion-proof.

- The electronic controller can be located far from the sampling site.

These wastewater autosamplers are self-cleaning.

- Lines are blown clear & dry after each sample, even in freezing temperatures.

Markland’s composite samplers for wastewater are the Simpler Samplers™.

- Using compressed air to move samples means no pump and no vacuum system to maintain.

- Needing only an air-line running from sampler head to electronic controller, with a second line running to the sample collecting bottle, means installation is simple.

Duckbil® Samplers are ideal for tanks, non-pressurized pipes, sumps, pits, open channels, sewers & lift stations.

- Help monitor for environmental regulatory compliance.

Program your wastewater composite sampler to operate based on time or by a flow meter.

- The option is always available to call in manual samples without affecting the normal sampling interval.

Customizable for your unique applications.

- Sampler head is available in aluminum, stainless steel & PVC, to meet the needs of diverse industries, such as food, mineral & chemical processing, power generation, pulp & paper, pharmaceutical and petrochemical manufacturing.

Get answers when you have questions

- Technical assistance is direct from the designers and manufacturers of this automatic wastewater composite sampling equipment.

Since 1967, Markland’s Duckbill® Automatic Composite Sampling System has been providing reliable, effective and efficient equipment (influent samplers, effluent samplers, wastewater samplers) for applications in diverse sectors:

- municipal water & wastewater treatment

- food, mineral & chemical processing

- power generation

- pulp & paper production

- pharmaceutical, petrochemical, and other manufacturing.

Markland wastewater sampling equipment installations include:

- tanks

- non-pressurized pipes

- sumps & pits

- septic systems

- open channels

- sewers

- outfalls

- reservoirs

- sewer pumping and lift stations

- clarifiers

- and more.

- Virtually no moving parts means reliable, trouble-free sampling; no pump or vacuum system to maintain.

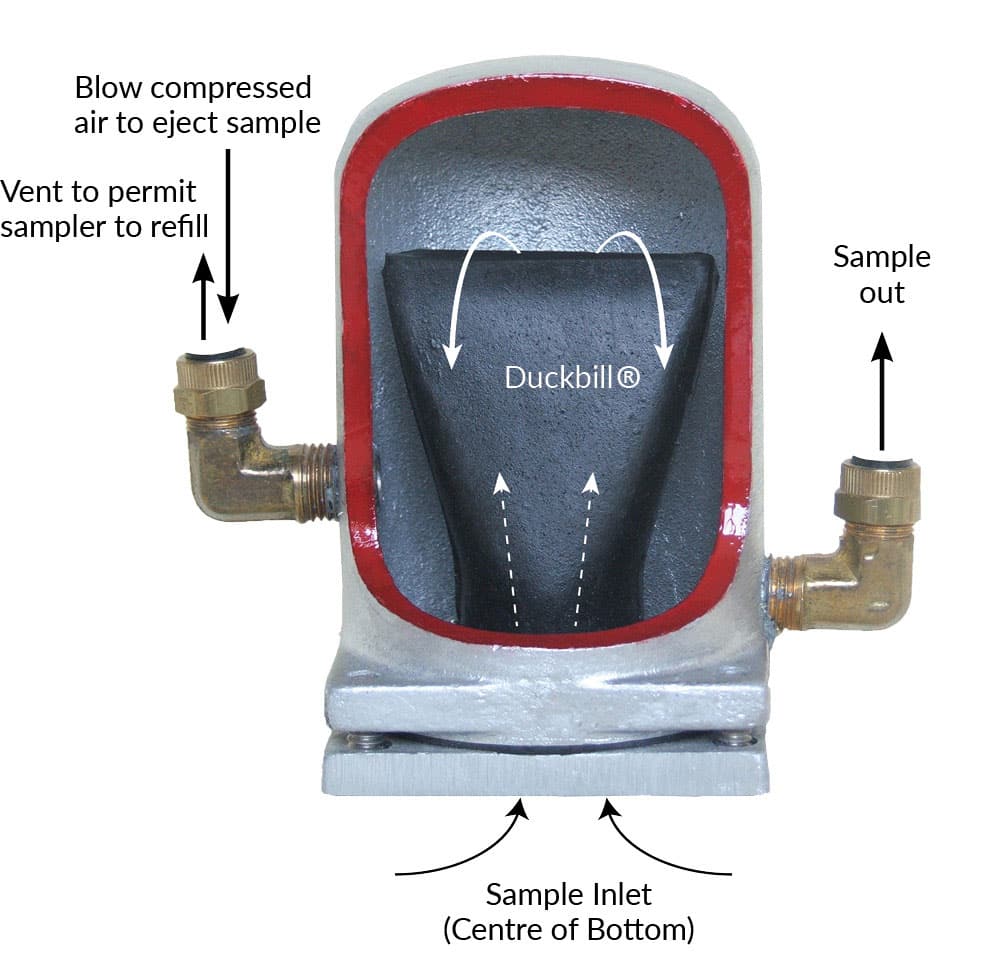

- Non-clogging, it requires little cleaning; Markland’s rubber Duckbill™ stops large particles from clogging tubes; each time a sample is taken, the Duckbill® closes down and expels any large particles, in a self-cleaning action.

- Lines are blown clear and dry after each sample is taken, preventing freezing in cold climates.

- The Controller can start a sample based on time or by a flow meter.

- Manual samples can be ‘called in’ at any time without affecting the normal sampling interval.

- The Controller can drive two Sampling Heads simultaneously, from two or more locations, simplifying installation and reducing costs.

- The Sampler Head is available in aluminium, 316 stainless steel, and PVC material (for different pH levels).

- Modular design allows components to be selected & assembled to suit your specific composite sampling requirements, including tubing and fittings, sample collecting bottles, refrigerators, small air compressors, regulators, etc.

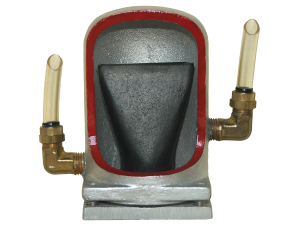

The Markland Duckbill® Sampler Head is submerged below the liquid level. The top fitting is vented to the atmosphere. Hydrostatic pressure forces a sample up through the vertical inlet in the base of the Duckbill®, continuing up through its slit, until the body of the Sampler Head is filled above the level of the top fitting but below the top of the Duckbill®. A trapped air pocket in the dome ensures the Sampler Head does not fill completely with liquid.

The Duckbill® Composite Wastewater Sampler is now ready to ‘call in’ a sample to the collecting station with a burst of compressed air. That compressed air is introduced through the top fitting, forcing a sample through the Sampler Head’s bottom fitting and to the collecting bottle. Reverse leakage of the sample back through the Duckbill® is impossible.

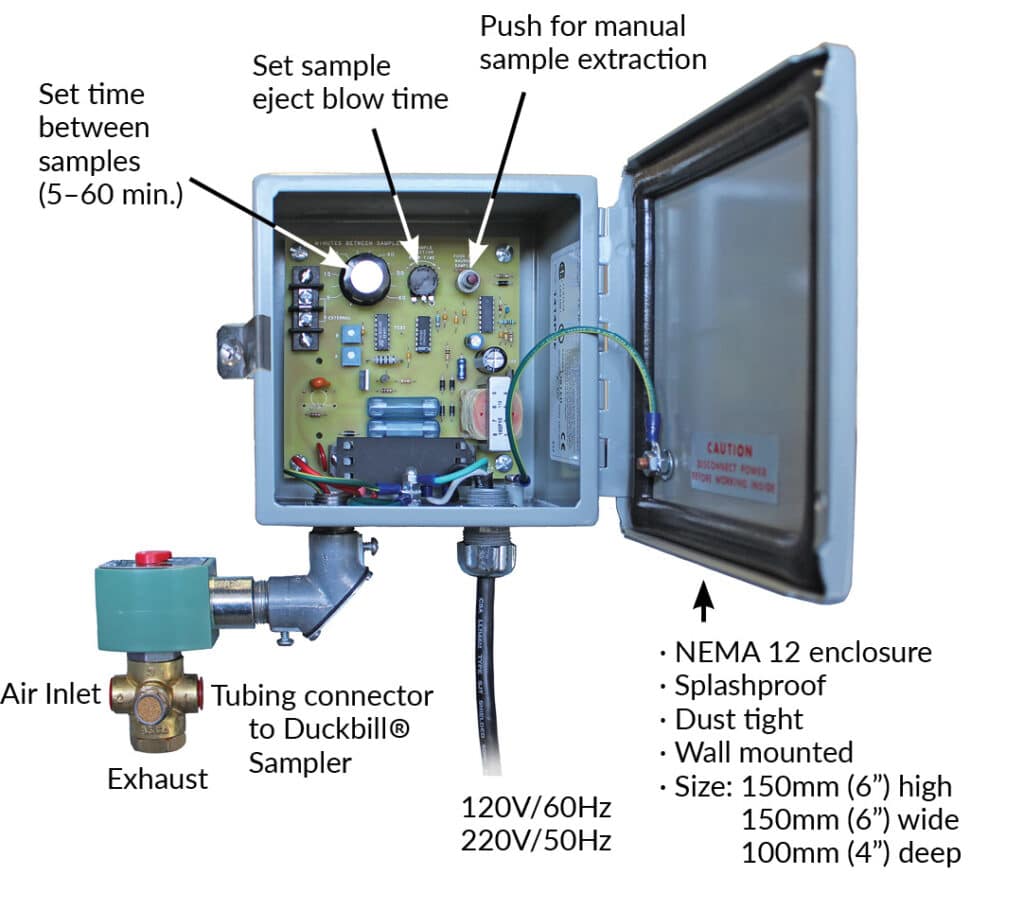

Markland manufactures automatic controls for 110 volt 60 Hz and 220 volts 50 Hz for clock sampling or flow proportional applications.

Your complete sampling system can be supplied, including tubing and fittings, sample collecting bottles, refrigerators, small air compressors, regulators, etc.— providing all the wastewater sampling equipment needed to create a customized influent sampler, effluent sampler or sewage sampler. Plant compressed air supply is not necessary.

Flow Proportional:

With the two external control terminals jumpered, a dial sets the time between samples. With the jumper removed and an external normally open (N.O.) contact connected, momentary closures cause one sample to be extracted for every closure. This gives samples proportional to flow when connected to a Flow Meter Totalizer Integrator Switch. In addition, by maintaining the external contact in the CLOSED setting, the Sampler clock will be turned ON, and will continue to run and extract samples at the time interval set on the dial, until the maintained closure is broken.

External Control Features:

External Control Features:

This versatile, multi-purpose composite wastewater sampler provides controls to meet your unique sampling needs. For example:

- Scheduled operation can be enabled by connecting the Markland Duckbill® Automatic Composite Sampling System Controller to a 24-hour timer, PLC or SCADA system.

- Intermittent operation can be achieved by connecting the Controller to a float switch that will turn the Sampler on when the liquid level rises, for example when stormwater runoff is being sampled.

- Operators can choose to extract samples only when a pollution parameter is out of limits, by connecting the Controller to a pH or other type meter.

- Start-up can be operated remotely by radio or telephone signals.

.

Sampler Head

Controller

This animated illustration demonstrates how the Duckbill™ Automatic Composite Sampling System works.

| Body Diameter | • 73 mm. (2-7/8″) |

| Overall Height | • 127 mm. (5″) |

| Mounting Lug | • Projects 16 mm. (5/8″) • Drilled two 7 mm. (9/32″) holes, 51 mm (2″) on centres |

| Sample Size per ‘Shot’ (Standard) | • 75 ml. (2 1/2 Oz.) • 50 samples = 1 U.S. Gallon |

| Duckbill™ Elastomers | • E.P.T. (Ethylene Propylene Terpolymer), standard• Buna-N (Nitrile), use only for oily wastes • Viton (Fluorocarbon), special order & extra charge |

| Materials: | Model RS-200-ALUM: Aluminum Alloy, Brass tube fittings, standard Model RS-200-SS: Type 316 Stainless Steel, Plastic tube fittings. Model RS-200-PVC: PVC Body, Plastic tube fittings |

| *PVC Remote Sampler is available to take 200, 300, 400, or 500 ml. per ‘shot’. Contact us for other sizes. | |

To receive a quote for a Markland Duckbill® Automatic Sampler System, please complete the form found below. The more technical details we receive from you, the better will be our recommendation.