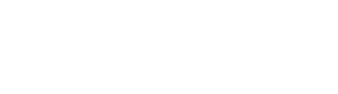

Markland is pleased to announce the arrival of the newest member of its family of process control instrumentation:

The Sludge Sleuth™

Improve efficiency. Improve effectiveness. Reduce costs.

Since 1967, Markland Specialty Engineering has been designing and manufacturing process monitoring and control instrumentation that is valued by operators, managers and consultants, in diverse sectors, around the globe:

- Municipal water and wastewater treatment plants use our equipment to measure primary, secondary, return-activated, and backwash sludge;

- Our equipment is used for Industrial processing and water and wastewater clarification in mining operations; petrochemical, pharmaceutical, food, mineral and chemical manufacture; as well as pulp-and-paper and power generation plants.

Get in touch!

THE MARKLAND ADVANTAGE

Reduce your energy and maintenance costs

- Run desludge pumps only when necessary.

Improve your chemical dosing

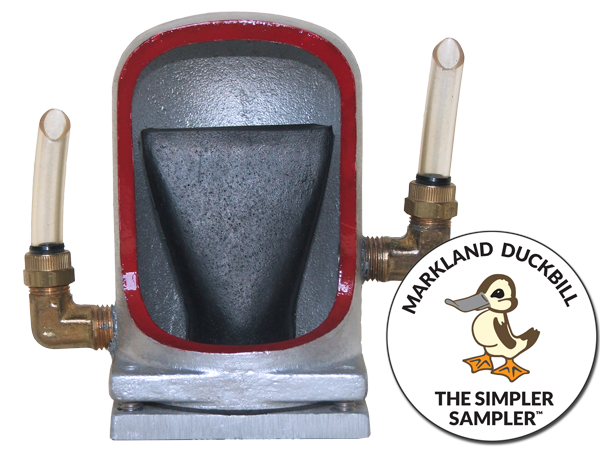

- Know the concentration of your sludge, slurry or silt.

Increase clarifier efficiency

- Maintain your preferred sludge blanket level.

Lower your costs for additional processing

- Maximize your sludge density and feed density.

Facilitate regulatory compliance monitoring

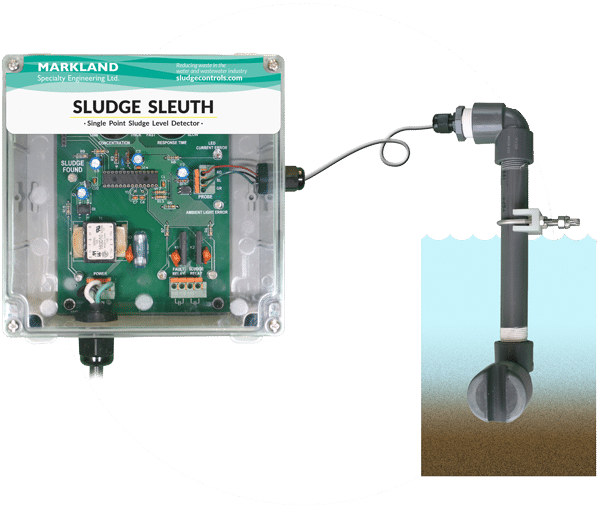

- Automate composite sampling even up high lifts, over long runs and in freezing temperatures.

We offer, at no-charge, a report of our instrument’s response to your material. Markland works to ensure that our products are well suited for each application, and has built a reputation for reliable instruments, factory-direct support and fast delivery

Since 1967, Markland Specialty Engineering has been designing and manufacturing process monitoring and control instrumentation that is valued by operators, managers and consultants, in diverse sectors, around the globe:

- Municipal water & wastewater treatment plants measure primary, secondary, return-activated, and backwash sludge;

- Our equipment is used for Industrial processing and water & wastewater clarification in mining operations; petrochemical, pharmaceutical, food, mineral and chemical manufacture; as well as pulp-and-paper and power generation plants.

The Markland Advantage

Reduce your energy and maintenance costs

- Run desludge pumps only when necessary.

Help prevent costly overflows

- Maintain your preferred sludge blanket level.

Improve your chemical dosing

- Know the concentration of your sludge, slurry or silt.

Lower your costs for additional processing

- Maximize your sludge density and feed density.

Facilitate regulatory compliance monitoring

- Automate composite sampling even up high lifts, over long runs and in freezing temperatures.

We offer, at no-charge, a report of our instrument’s response to your material. Markland works to ensure that our products are well suited for each application, and has built a reputation for reliable instruments, factory-direct support and fast delivery